CONVEYORS

Mobil Conveyor Capable of Flexile Motion

Mobil Conveyor Capable of Flexile Motion

This technology gives opportunity in storaging, stocking up, loading, unloading, transfering of packaged or sacked goods by an easier and faster way. By operating input and output conveyors independently and keeping end part parallel in all angular cases, the machine provides confortable loading / unloading processes. Parallelism system is designed by using steel cables to provide much longer running life.

Thanks to mobile wolking system of the conveyor, it is possible to change the machine’s position and direction with easy maneuvers without requiring manpower. Front and rear axles has capability of movement independently and this property gives opportunities to change the location and direction of the machine even in small areas. The machine can move like a crab thanks to it’s wheels maneuver capability up to 90 degrees that means fully vertical to the conveyor axis.

The long part of the conveyor can rise from 1,2 m up to 9 m (depends on customer demands) by using a hydraulic system which is equipped with scissors to enable whole machine’s running life to become longer and consistent. Scissors system also prevents possible torsions on this long part of the conveyor. This well designed system requires shorter hydraulic cylindir which requires less hydraulic fluid and energy consumption as well.

Two independent electric motors (with reducers) are directly accoupled with driving drums which also equipped with speed control devices. This part of our design quaranties much longer running life with more consistent operation.

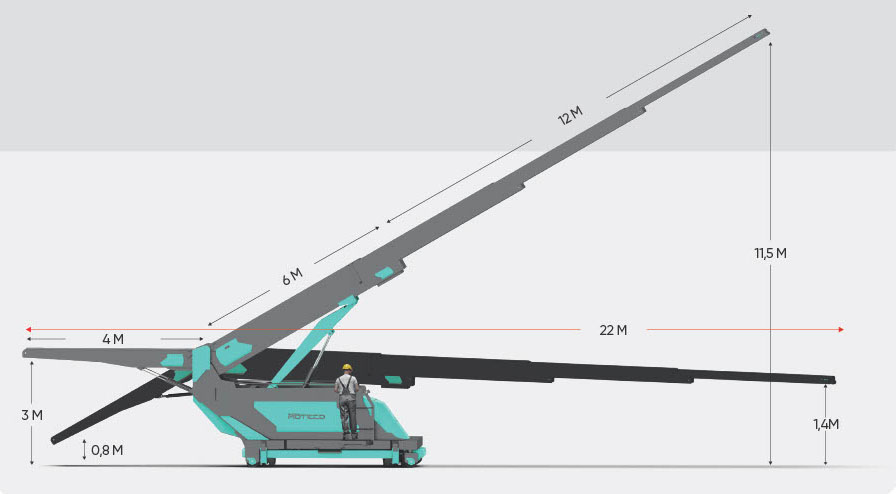

MOTECO-18 Mobile Telescopic Conveyor

With 22 m line length and 11.5 m height stacking, MOTECO walking systems provide high manoeuvrability even in narrow spaces. MOTECO, which is designed completely user-oriented, increases work efficiency and work safety to a high extent.

MOTECO-15 Mobile Telescopic Conveyor

With its 19 m line length and 9.5 m height stacking, MOTECO walking systems provide high manoeuvrability even in narrow spaces. MOTECO, which is designed completely user-oriented, increases work efficiency and work safety to a high extent.

Telescopic Conveyors

Telescopic conveyors are designed to realize vehicle loading/unloading processes with easier, faster and safer solutions. These conveyors can be extended in to the vehicle automatically.

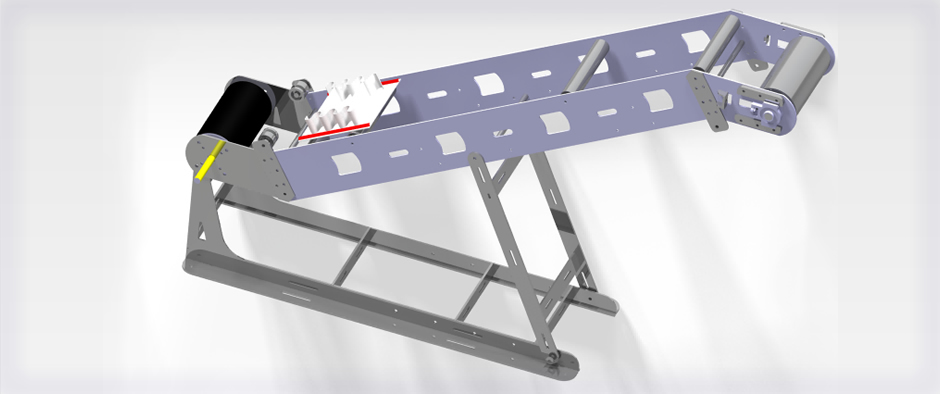

Mobil Conveyor Capable of Flexile Motion

Mobil Conveyor Capable of Flexile Motion

This technology gives opportunity in storaging, stocking up, loading, unloading, transfering of packaged or sacked goods by an easier and faster way. By operating input and output conveyors independently and keeping end part parallel in all angular cases, the machine provides confortable loading / unloading processes. Parallelism system is designed by using steel cables to provide much longer running life.

Thanks to mobile wolking system of the conveyor, it is possible to change the machine’s position and direction with easy maneuvers without requiring manpower. Front and rear axles has capability of movement independently and this property gives opportunities to change the location and direction of the machine even in small areas. The machine can move like a crab thanks to it’s wheels maneuver capability up to 90 degrees that means fully vertical to the conveyor axis.

The long part of the conveyor can rise from 1,2 m up to 9 m (depends on customer demands) by using a hydraulic system which is equipped with scissors to enable whole machine’s running life to become longer and consistent. Scissors system also prevents possible torsions on this long part of the conveyor. This well designed system requires shorter hydraulic cylindir which requires less hydraulic fluid and energy consumption as well.

Two independent electric motors (with reducers) are directly accoupled with driving drums which also equipped with speed control devices. This part of our design quaranties much longer running life with more consistent operation.

Gıdaların Üretim Esnasında Metal Partiküllerinin Temizlenmesi - (kopya)

Gıdaların güvenli ve kaliteli olması, tüketiciler için öncelikli bir konudur. Ancak, gıdaların üretim sürecinde metal partiküllerinin bulunması, gıdaların güvenliğini ve kalitesini tehdit edebilir. Bu nedenle, gıdaların üretim esnasında metal partiküllerinin temizlenmesi önemlidir.

Portable Conveyors

Portable conveyors

Portable conveyors are produced in different masses and dimensions. It can be designed as wheeled, sliding systems and sled types. For different use and designs please contact with enginnering department.

Trigger/Plane Belt Conveyors

Trigger/plane belt conveyors

These conveyors are generally used for conveying, rotating and aligning of plate or pannel shaped products. Those can be designed and produced in all types and dimensions. For different use and designs please contact with enginnering department.

Crusher/Mine Conveyors

Crusher/mine conveyors

These conveyors are used in the field of crushing and mine industry. In mine industry, materials need to be continuously transfered from a point to another point. Accordingly horizontal or inclined conveyors are used. Length of these conveyors are variable depends on distance of transportation. In this field belt conveyors are usually prefered. There are several types of belts according to material will be conveyed. Engineering study should be fulfilled according to specifications of goods will be transfered. For different use and designs please contact with enginnering department.

Curved or Modular Conveyors

Curved or modular conveyors

These conveyors are used in the field of nonlinear curvature places. Modular parts differ according to clasification and specification of goods will be transfered. It can be produced with moduls made of plastic or metal. It is generally used in food industry. For different use and designs please contact with enginnering department.

Passage Conveyors

Passage conveyors

These conveyors are used in the field of linear or nonlinear passage points to enable good to be transfered from a conveying line to another conveying line. Modular parts differ according to clasification and specification of goods will be transfered. It can be produced with chain or belt moduls. It is generally used in cargo and logistics sector. For different use and designs please contact with enginnering department.

Horizontal Transfer Conveyors

Horizontal transfer conveyors

These conveyors are used to convey bulk, pieced or packed goods. It can be produced as monoblock or entegrated multi sections. For different use and designs please contact with enginnering department.

Z Type Conveyors

Z Type Conveyors

We produce any kind of conveyors depends on buyer’s requirements in all forms and dimensions.

For different use and designs please contact with engineering department.

Elevator Buckets

Elevator Buckets

These products are used especially in food industry to transfer goods like seed, legumes and dried fruit and nuts vertically or horizontally. It is very useful system for vertical lifting of dry goods. Fixed or portable models are available. For different use and designs please contact with enginnering department.

Vibrating Conveyors

Vibrating Conveyors

These conveyors are used to transfer goods in forms of powder, granul or small piece. Flow speed can be choosed by means of vibrator power that is adjustable. Please contact with enginnering department for models suitable for your needs

Automated Magnetic Seperator

Automated Magnetic Seperator

Automated magnetic seperators are used for separating metal particles from raw materials. In food processing industry, plastics processing and pharmacy industry etc., it is necessary to be entegrated in to the system. Standards implemented for food industry require minimum 18000 gauss magnetic power. We are able to produce in variable capacities and sizes according to buyer’s requirements and demands.

Cleaning process is provided automatically and timing limits are adjustable by applying setting values. By means of this property it is not necessary to stop production line. Metal particules are collected in bunkers entegrated to the system.

Please contact with us for your needs and design specifications of your production line.