SPARE PARTS

CONVEYOR ROLLERS

Conveyor rollers are essential components used in conveying processes. These rollers come in different sizes, materials and properties

Conveyor rollers are important components used to perform various operations. Selection and regular maintenance of the rollers in accordance with the business needs are very important for an efficient conveyor system. As Kayzer Conveyor, we produce with the principle of quality materials and quality workmanship, you can get an offer from us for your consumables and maintenance works.

|

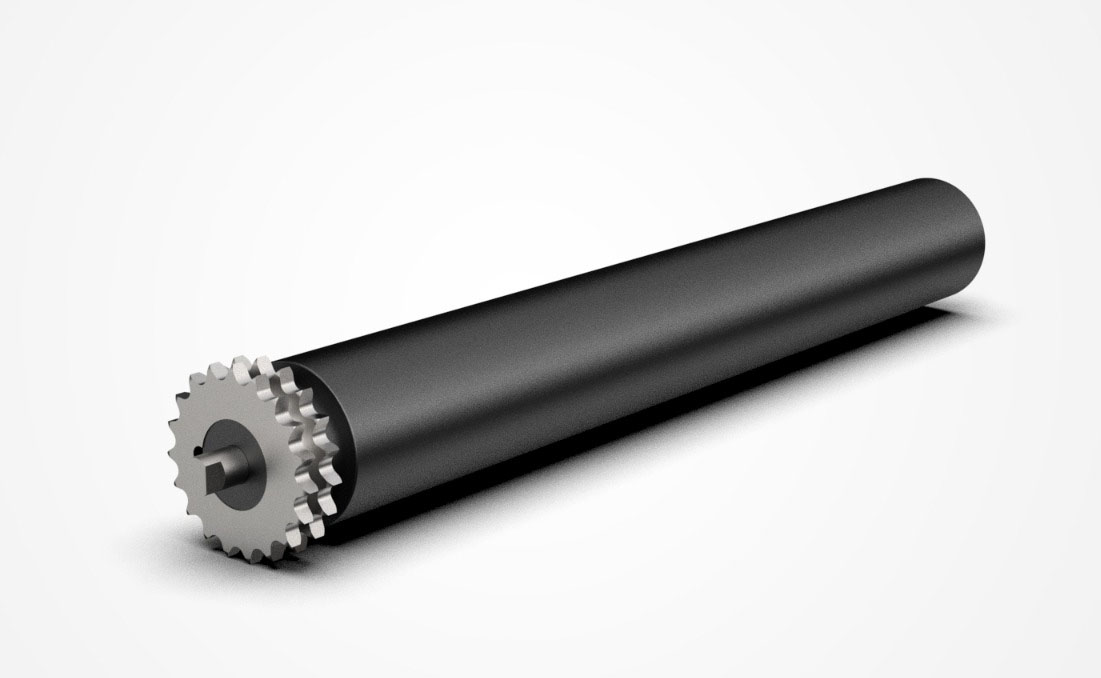

Drive Rollers: These are the rollers that move the conveyor belt and provide the power. These rollers are controlled using chain or belt drive systems. |

|

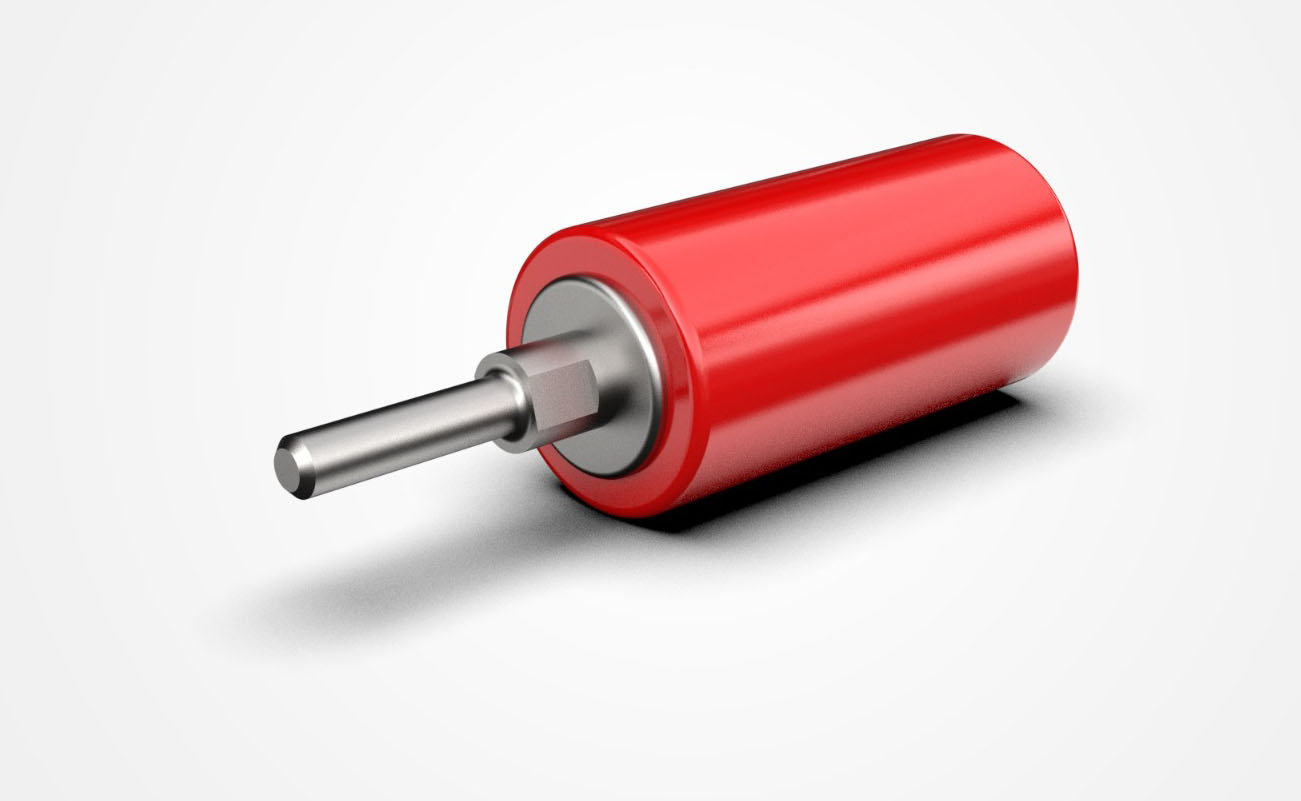

Carrier Rollers: These are the rollers that support and carry the loads carried on the conveyor belt. |

|

Directional Rollers: They ensure that the conveyor belt moves in a planar direction without slipping on the conveyor. These rollers keep the conveyor belt stationary by applying compression pressure. |

|

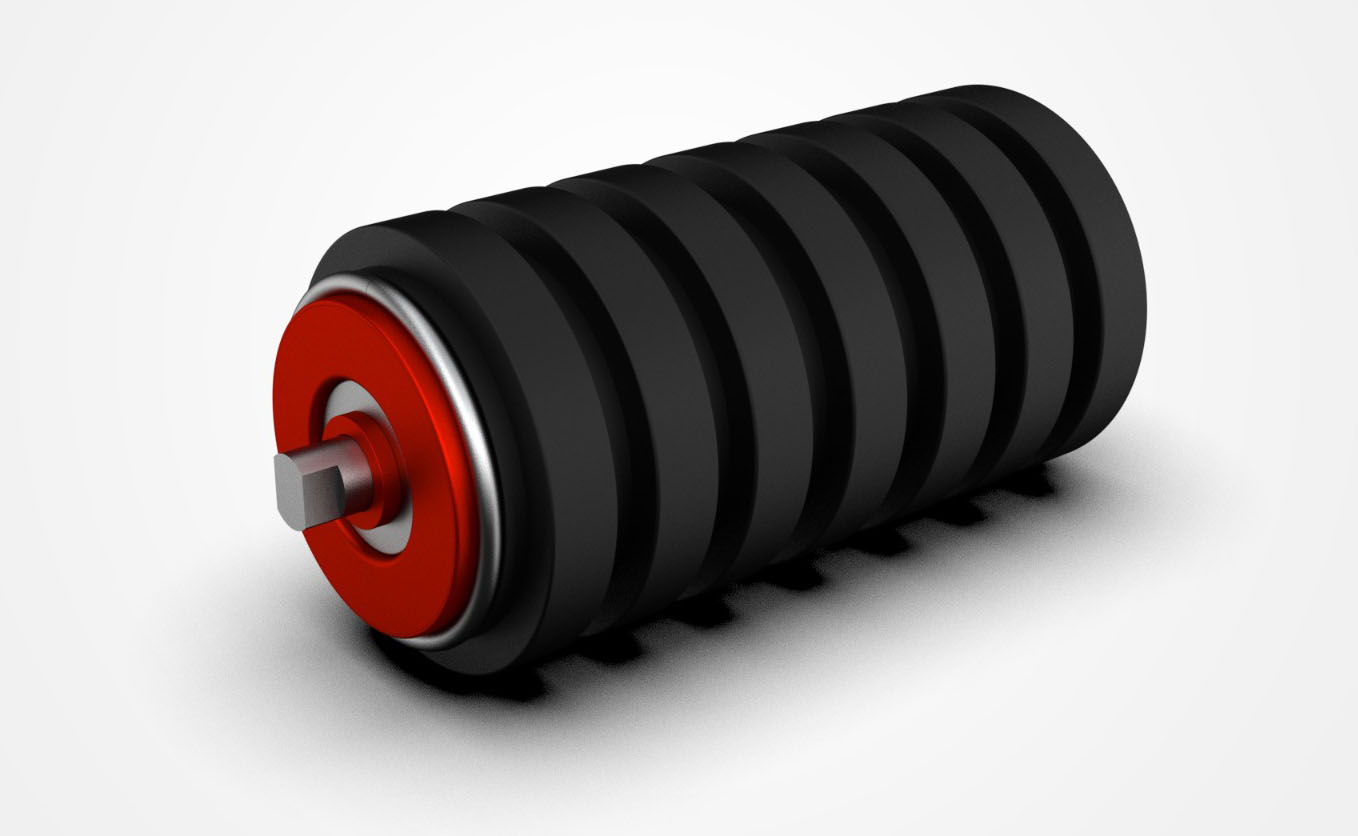

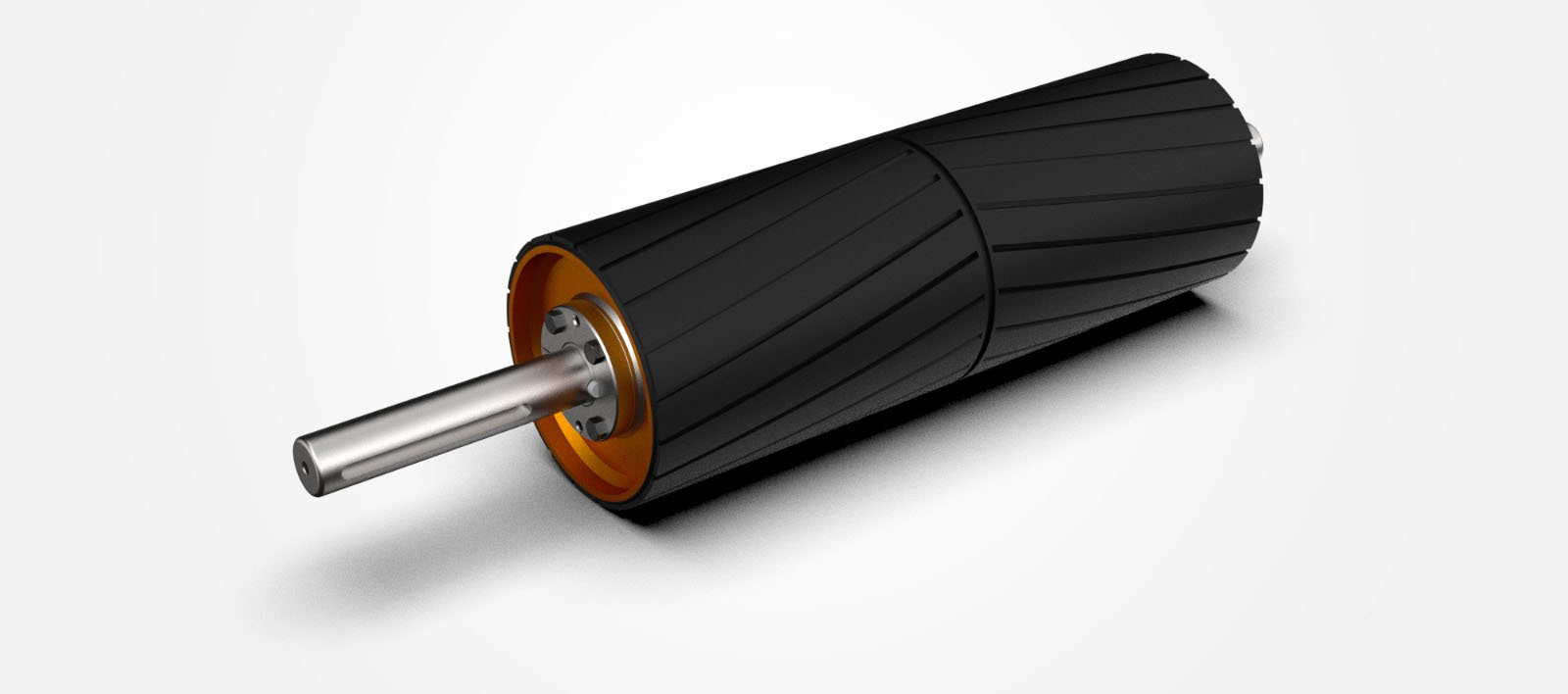

Shock Absorbing Rollers: These are special rollers designed to reduce the impacts that may occur in loads carried along the conveyor system. These rollers allow the loads to fall more gently on the conveyor belt thanks to the rubber outer rings. |

INDUSTRIAL OVEN ROLLERS

Kayzer Makine offers reliable solutions for industrial furnaces at high temperatures. Our furnace rollers are made of steel, cast iron and ceramic materials that offer a combination of temperature resistance and high load carrying capacity.

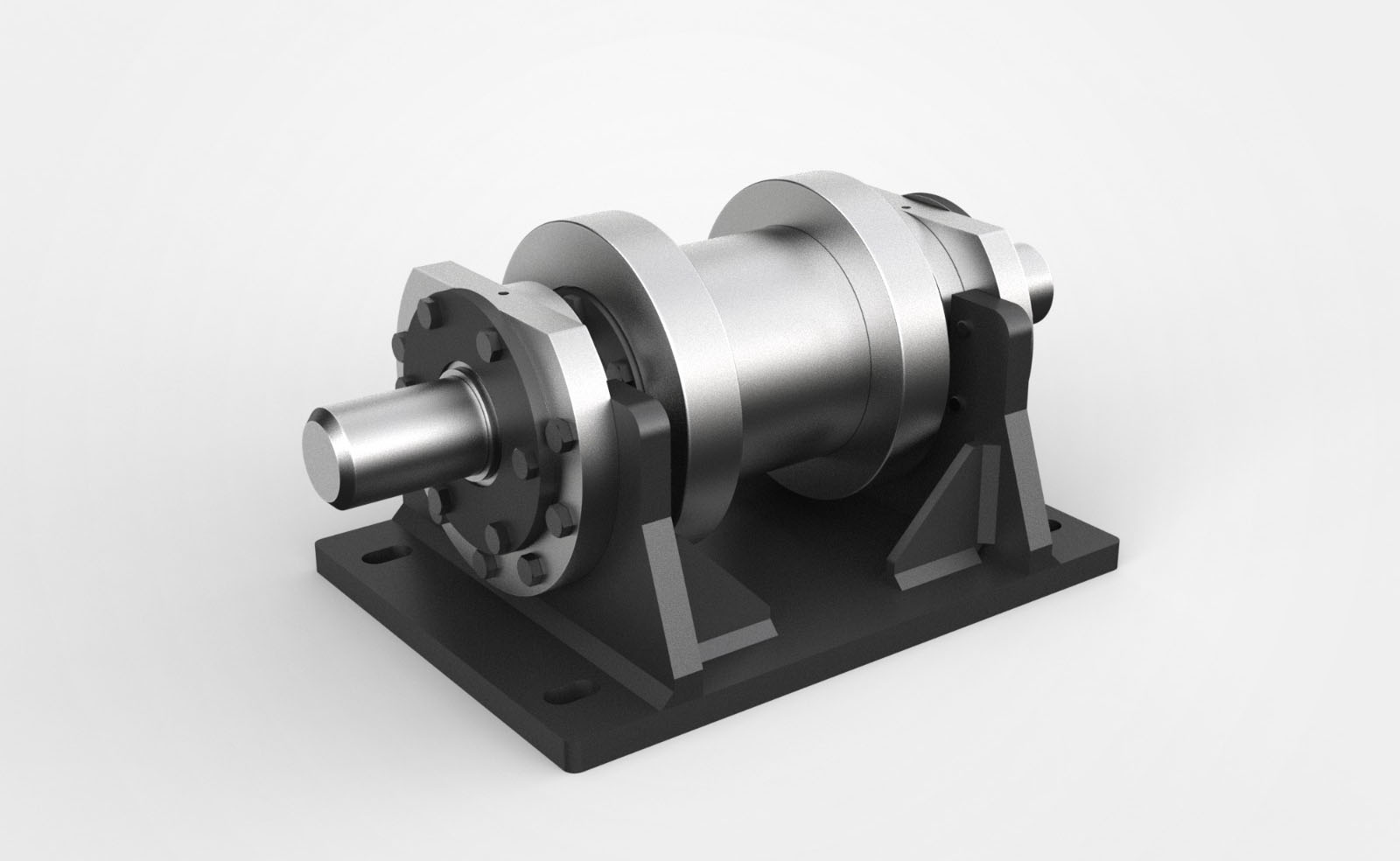

CONVEYOR ROLLER STATIONS

Conveyor roller stations are part of material handling systems used in industrial production facilities.

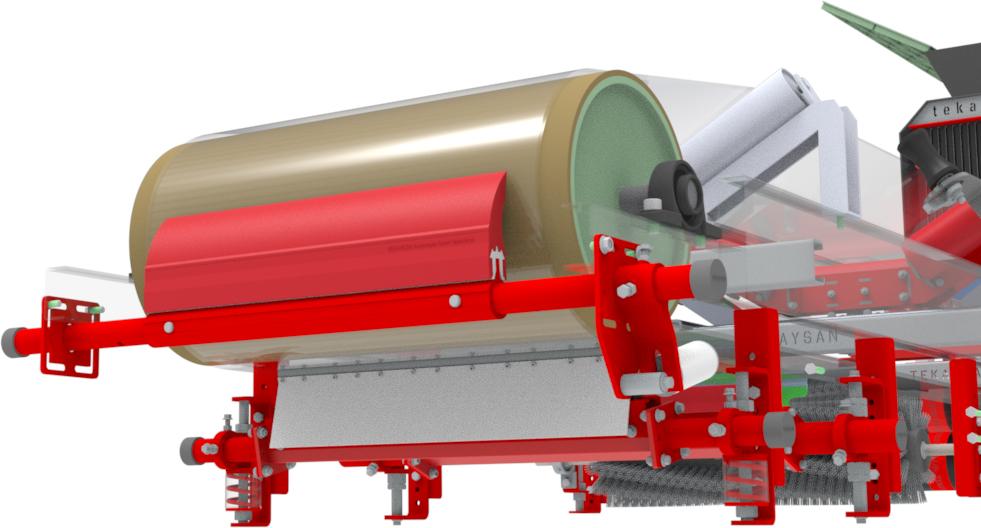

CONVEYOR DRUMS

Conveyor drums are an important component used in the transportation of materials. Conveyor drums are one of the most important parts of the conveyor and are subjected to a large workload during the transportation of materials. Therefore, choosing the right drum is the key to a long-lasting and reliable conveyor system.

CONVEYOR ROLLERS

Conveyor rollers are essential components used in conveying processes. These rollers come in different sizes, materials and properties

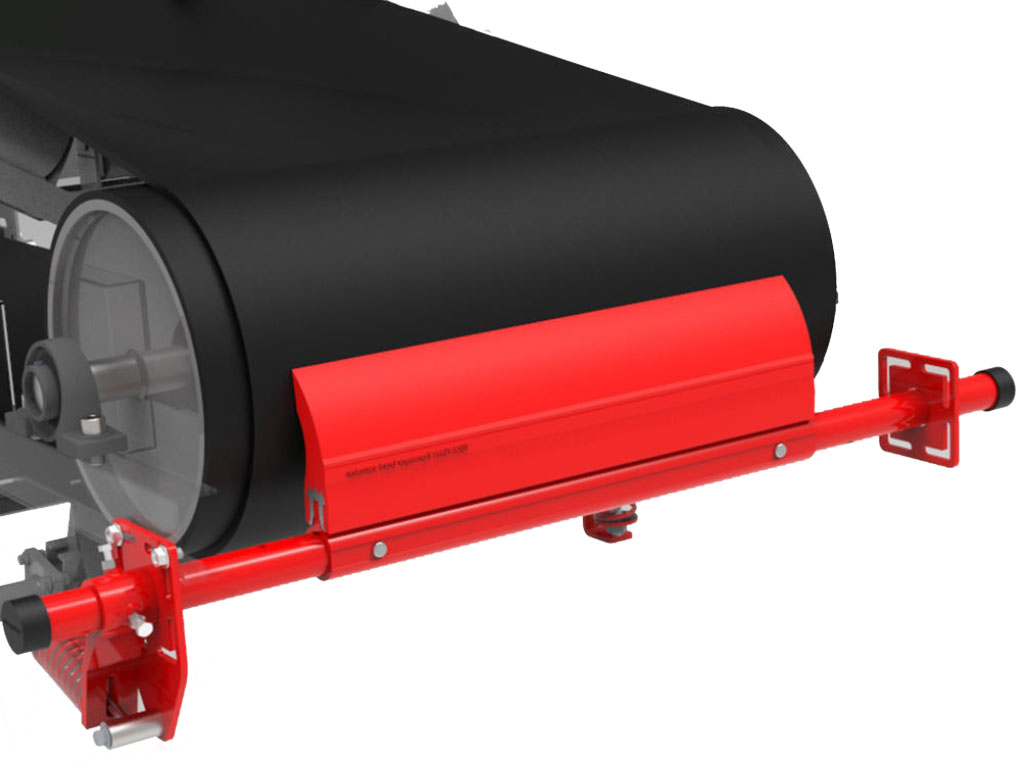

EXTRA HEAVY TYPE SECONDARY SCRAPER

Secondary scrapers are designed for the final cleaning of belts and have high performance in removing fine dusty or damp sticky materials from the belt surface.

HEAVY TYPE PRIMARY SCRAPER

Polyurethane tipped primary scrapers are designed to provide high scraping performance in the most difficult and severe conditions.

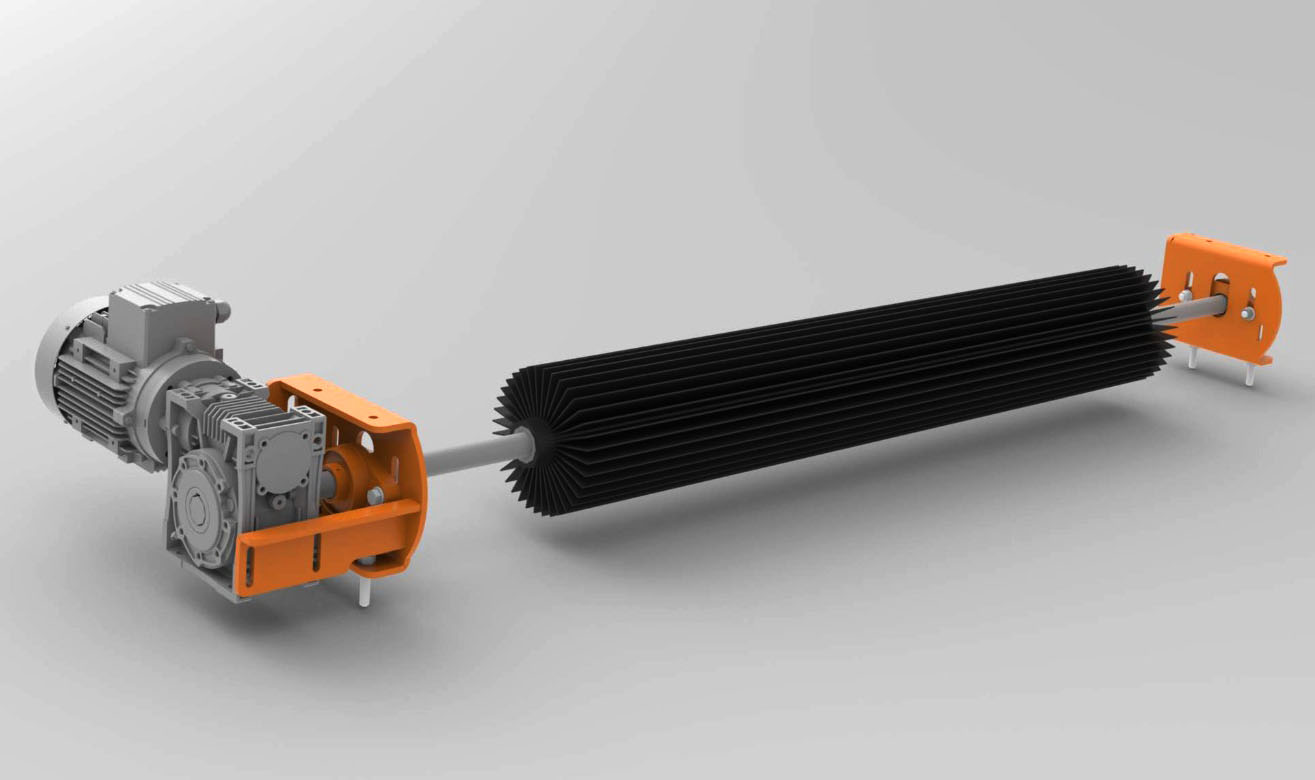

CONVEYOR BELT CLEANING BRUSHES

What are Conveyor Belt Cleaning Brushes?

Conveyor belt brushes are industrial cleaning equipment used in conveyor systems. They are designed to remove dirt, dust, debris and other substances that accumulate on conveyor belts. These brushes are widely used in production lines for cleaning, polishing, lubricating or material handling.