CONVEYOR BLOG

SOLID MODELING IN MACHINE MANUFACTURING PROCESS

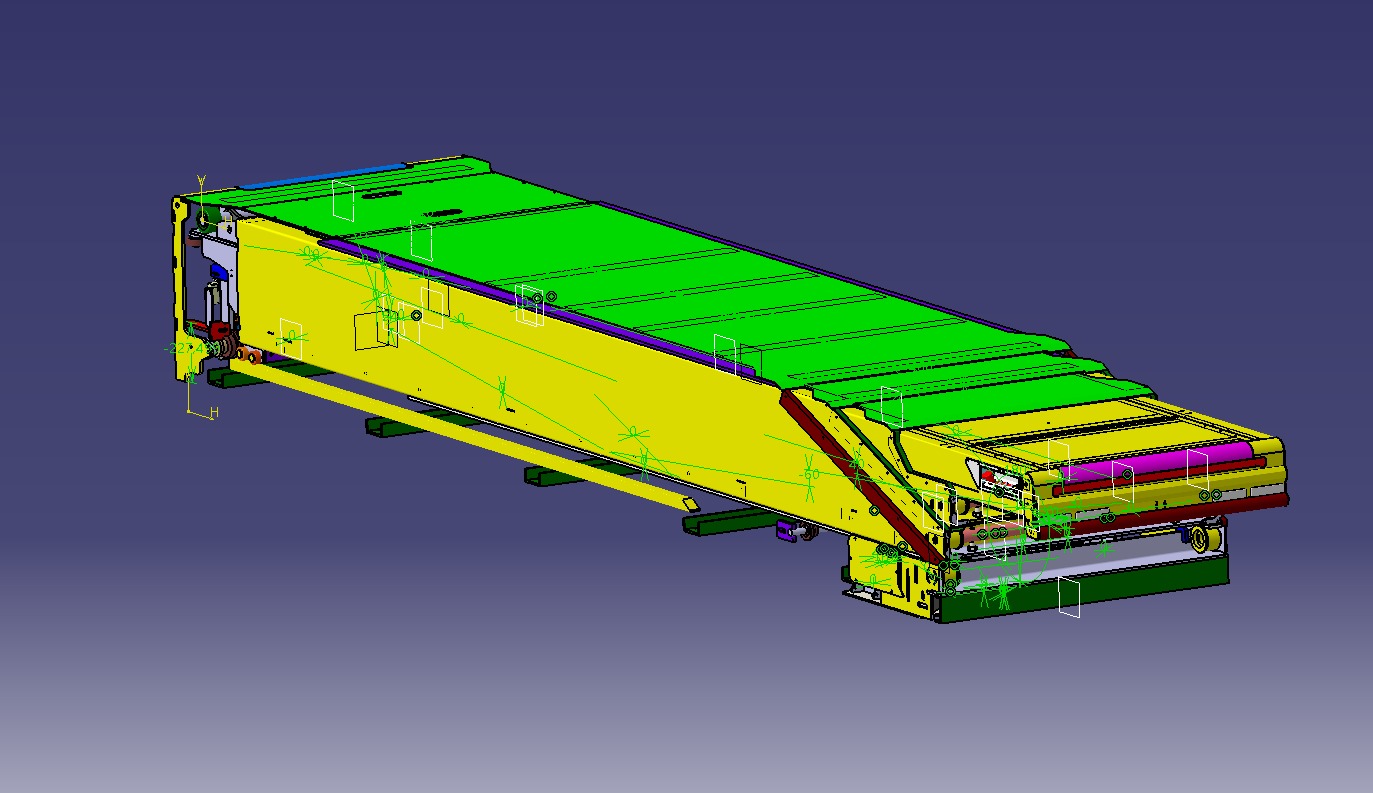

The design of a solid model for the manufacture of a machine is carried out by the design team. The design team creates a design using CAD software, taking into account customer requirements, technical specifications and the materials to be used in the manufacturing process. This design includes the dimensions, shapes, features and other details of the machine parts.

Solid model design is also very important in pre-production prototyping. In prototyping, the design team creates several different models to test and refine the design. These models are tested and necessary changes are made before finalizing the design.

Solid model design is also used by CNC (computerized numerical control) machines used during machine manufacturing. These machines read the CAD file of the design and perform operations such as cutting, drilling or shaping parts.

Solid model design is one of the most important stages of a machine manufacturing process. This stage is essential for the reduction of errors in the manufacturing process and for the correct production and assembly of machine parts and components. Therefore, it is very important to design a quality solid model for the machine manufacturing process.

After preliminary preparations such as exploration and measurement, our company prepares the entire design of the machine to be manufactured in CAD environment and starts production with customer approval after all necessary controls and calculations are made in computer environment before the production process. Our primary goal is to meet the needs of our customers in the most efficient way. You can contact us for a professional service.

SOLID MODELING IN MACHINE MANUFACTURING PROCESS

CONVEYOR BELTS IN TERMS OF FOOD SAFETY

Telescopic Conveyors: Accessible and Flexible Load Handling Solutions

Steel Construction?